Written and Presented by:

- Wilson Peppard – Oncor Electric Delivery

- Troy Vaughn – Principle Services, LLC

Every project and program manager has felt the squeeze of a sliding start date while their in- service date remains fixed. It is not a comfortable feeling, and the pressure often causes anxiety, turf battles, and conflict amongst members of the project team. In the case of the Lubbock Power & Light (LP&L) Integration into the ERCOT System, the squeezed program consisted of an estimated $364 million transmission buildout.1 Regulatory discussions took longer than originally anticipated, but

LP&L’s cutover date to ERCOT remained firm. As the Certificate of Convenience and Necessity (CCN) effort kicked off, one executive associated with the program looked across the table at his team and asked the reasonable question, “Three years … Is it possible?”. The answer, while not without caveat, was a qualified “yes”, but everyone knew that it was going to be a challenging program. This paper is intended to communicate some of the history, a few of the technical details, and a story of the teamwork that it took to complete the LP&L interconnection on time and under budget.

Brief History:

LP&L was connected to Southwestern Public Service Company (SPS) and under contract for their total power requirements through May of 2019 (which they later extended through May of 2021). In 2013, LP&L began to look at how they would fulfill their power requirements in the future. In addition to considering new generation options, LP&L investigated entering the deregulated market of ERCOT, submitting a request to the PUCT in December 2015. Following LP&L’s request, the PUCT ordered ERCOT to investigate this scenario in February of 2016, through PUCT Project Number 45633. In June of 2016 ERCOT published its findings after studying over 40 transmission integration alternatives. Their exercise resulted in a recommendation of Option 4ow that best met cost effectiveness and planning reliability criteria. This transmission solution connected the LP&L grid to three existing Sharyland Utilities LP (Sharyland) 345kV switchyards. In March of 2018, Docket 47576, the PUCT ordered LP&L and Sharyland to build the necessary transmission infrastructure to connect LP&L to ERCOT, leaving it up to the utilities to determine the best split of ownership and project execution. This order confirmed 6/1/2021 as the reasonable integration date that matched the expiration of LP&L’s existing power contracts.2

The issuance of the Final Order in Docket 47576 kicked off a new phase of the program for the utilities. LP&L and Sharyland now had to collaboratively begin the routing and CCN process. At first there was a natural tension as both parties presented their perspective on how things should get done, but quickly, through good leadership, all organizations began working together through the significant volume of work needed to hit the June 2021 completion date. The first CCN, Docket 48625, was filed at the PUCT in September 2018. Both Sharyland and LP&L were actively working on the subsequent three CCNs when in October 2018, it became public that Oncor Electric Delivery Company was purchasing

Sharyland’s panhandle-area assets. This corporate transaction posed a significant challenge for the team as complex and detailed CCN work transitioned from Sharyland to Oncor. More details in the CCN effort are discussed later in this paper.

The collaborative teamwork with LP&L carried forward, from Sharyland to Oncor. Typically, in ERCOT, when two utilities build a t-line between their respectively owned stations, each would build out to a midpoint structure, divide ownership at that structure and be done with it. They might coordinate on the CCN, but each would handle their respective engineering, procurement, and construction. In this case, LP&L and Oncor coordinated the CCNs, right of way acquisition, facility designs, procurement, construction efforts, and ultimately all challenges that faced the 4ow program.

4ow Scope of Work:

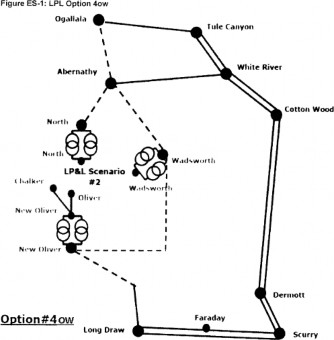

ERCOT’s response to PUCT Project Number 45633 demonstrated that transmission solution ‘4ow’ not only addressed LP&L’s request to interconnect with ERCOT, but it also addressed the long-term plan to “increase the export capacity from the Panhandle” generation resources.3 Sharyland’s transmission assets in the panhandle, that were built during the Competitive Renewable Energy Zones (CREZ) program, provided two northern, 345kV interconnection points (Ogallala and Abernathy stations). Sharyland also had a southern point of interconnection that tied to the West Texas oilfield load which was relatively close to the southern connection point for LP&L. ERCOT’s map of 4ow is shown below in Image #1.

As explained in detail in the four CCN filings, Oncor built all the 4ow prescribed transmission assets. This included all 345kV transmission lines, 345kV switchyards, the six 345/115kV transformers, New Oliver Substation, and the 115kV lines that connected New Oliver to LP&L’s existing grid. LP&L will ultimately own 50% of the 4ow transmission assets.5 While Oncor tackled the 4ow engineering, procurement, and construction, LP&L was able to focus most of its efforts on the significant volume of work required to prepare its existing transmission system for connection to the 4ow transformers.

During the CCN routing efforts, the utilities discovered two major modifications that were required to the 4ow plan. The first came after the routing team identified significant urban density around Chalker Substation. 115kV line routing would have been extremely difficult, impactful to landowners, and expensive. The utilities proposed to ERCOT who subsequently approved a change in the POI from Chalker to Southeast station. The second change was the relocation of a POI from existing Wadsworth station to a new station location in CCN 48909. During geotechnical investigation, the team discovered steel cables, carpet, paper, and other debris that came up with the boring. This debris was from a 1970 tornado that hit the city of Lubbock and it created subsurface conditions that were not suitable for a station expansion. This change adjusted the electrical connection points from 4ow and altered the geographical connection that impacted the in-progress CCN. ERCOT approved the electrical modifications in November 2019 and geographical changes were approved in the final order of the CCN.6

The collaboration, trust, and teamwork executed between LP&L, Oncor, and their contractors enabled the parties to successfully complete the 4ow scope ahead of schedule, under budget, and within scope.

A Culture of Teamwork

When reviewing the various elements of the project upon Oncor’s acquisition of Sharyland Utilities panhandle-area assets it was clear that the schedule was going to be a major pressure throughout the program. Based on how the CCN’s were filed it would leave 14-17 months to procure ROW, complete design, construct, and commission the assets. This is a shorter timeline than desired for 345 kV transmission lines of 30-60 miles in length especially when many are being completed in parallel with each other. As a schedule was developed this timeline seemed possible but left very little room for any of the multitude of issues that often arise on “greenfield” projects. In order to meet this timeline typical project management practices were used but ensuring a cohesive team was in place was critical to efficient completion of applicable projects. Below are the strategies that we used to ensure that we nurtured a culture of teamwork with all resources.

- We dedicated resources whether internal or contract to focus solely on the program rather than allowing them to split their attention on projects external to the LP&L program. Rather than dividing workload between multiple contractors/consultants we utilized larger organizations that could handle the entirety of their portion of the scope for the program. For example using a single firm for items such as Geotech, ground survey, aerial survey, construction inspection, and a single engineering firm for all but one project. This was important to ensure all internal and external stakeholders were heavily invested in the success of the program.

- It is always important to have clear written scopes and goals for all resources; however, sometimes these documents do not always permeate throughout all stakeholders working on a task at different levels of organizations. To combat this we attempted to engage resources through a program kick-off meeting. The meeting emphasized the criticality of communicating risks/issues and ideas for improvement, minimizing cost, and maintaining the schedule. This ensured that all program resources were aligned in the processes, goals, and vision for the program.

- As a result of expected CCN approval dates the initial schedule was not set up to allow for a typical waterfall of resources being able to move from one project to the next. To combat this

issue, we split projects into mini-projects in order to allow certain project resource teams to work on multiple portions of the program rather than one larger portion. This repetition of tasks resulted in improvement of coordination on the later projects that had tighter schedules.

It was not only important to build a culture of teamwork within Oncor project teams, but also to maintain this with our program partner, Lubbock Power & Light. The importance of a close working relationship with LP&L leadership and its key contractors was elevated due to the unique nature of the situation wherein Oncor engineered, procured, and constructed transmission assets for LP&L. The rapport that was developed between organizations meeting together, prior to COVID, was of critical benefit during the peak of the project in late 2020 and early 2021as project issues arose and partnership was needed for joint solutions. As a result of this established trust, the door was opened to be able to communicate not only real risk, but also potential risk, as we tracked the project throughout.

Project Management vs Program Management

Another element critical to the project’s success was the separation of project management and program management. On smaller programs, sometimes these functions are essentially shared by one person. It can be very difficult for an individual to be fully knowledgeable of the details of a project and also to “zoom out” to see the big picture. Project Managers can have a large impact on how well project teams stay on schedule. There are portions of a project where multiple diverse resources may need to complete steps of a process or collaborate to make a decision. These resources must operate in sync with each other, similar to a dance. If utilizing email or “one on one” conversations it can sometimes take one to two weeks to make the decision or complete the process. Project Managers’ oversight of these critical engagements can advance this to 1-2 hour challenges from 1-2 week challenges. Key functions of the Program Manager are tracking and mitigating major project risk as escalated through the Project Managers. The Program Manager is also a check on the Project Manager to ensure that critical steps in the schedule are not missed.

As a result of the concepts above we laid out the following “Critical Success Factors” for our Program and Project Managers:

- Consistent Schedule Execution – Ensure targets are measured and met

- Cohesive Problem Solving – Quick resolution and mitigation plans as issues arise

- Communication – Effective communication of status and issues across teams and external stakeholders

CCN Lessons Learned

All four CCN applications had been filed and were in process upon Oncor’s acquisition of Sharyland’s assets, and as a result Oncor had to make many decisions that varied from our typical process.

- During Sharyland asset acquisition approval process, Oncor filed testimony in the CCN cases. Several of the CCN’s would be well developed, and not all Sharyland testimony/plans would align with Oncor plans and/or standards

- Upon the transaction completion, resource decision had to be made to determine how to continue to use existing resources and filed testimony. In the end, the EA/routing resources were maintained and Oncor stakeholders and contractors were inserted into other CCN roles.

- All 4 CCN’s originally proposed to utilize Sharyland standard conductor and structures. Oncor filed testimony that maintained the same structure types as previously proposed but updated Oncor standard towers and wire. This resulted in utilizing a smaller ACSS/TW conductor rather than a larger ACSR conductor.

- CCN 48909 tied four existing stations to a new substation. Sharyland determined that the PUCT would want alternative locations for the new substation, so the number of viable route alternatives was extensive. Capturing these alternatives and articulating them to the commission and interveners was complicated. With hundreds of possible alternatives, Sharyland and LP&L filed the CCN application by articulating a 115kV line (SNO) and a 345kV line (WNF) that would each pass through on of the alternative new station locations. The PUCT ultimately published two orders to articulate their mandates for this CCN application.7

- Phase 1 Environmental Assessments and Geotech borings are critical at potential station locations. If involved in a CCN process, doing these efforts prior to filing may save rework.

- As the CCN projects were in mid-flight, analysis had to be completed on the estimates to determine if they needed to be updated by Oncor. In the end, the decision was made to stick with the existing SU estimates.

Right-of-Way Acquisition

ROW acquisition was key to the success of the program. A few key lessons learned are below:

- It was beneficial to break up the transmission lines into “mini projects” for every few miles. This allowed agents to better prioritize acquisition to ensure that the line could be constructed in a linear fashion.

- In areas where landowners primarily live on the subject properties and use the land for farming it is especially helpful to utilize agents that are from the area and that understand farming the way the landowners do.

- As functional questions arose from landowners, it was helpful to have an engineer in the area to be able to meet with the ROW agents and landowners to discuss options. This often allowed for quick resolution. Additionally, we found that the landowners often appreciated this collaborative approach.

- A major challenge for ROW acquisition in the program was that most of it was completed during the COVID-19 Pandemic. This introduced extra challenges for ROW agents and created complications in legal proceedings. We found that judges in different counties were operating differently as a result of the pandemic and required us to modify process on a per county basis. We generally were able to continue to have “in-person” hearings throughout the acquisition period with a video conference option.

Engineering & Procurement

The engineering teams that completed these projects all worked on multiple projects throughout the program. As a result, the coordination and speed of work increased throughout the program as design was consistent throughout the projects. Early issues, such as how to handle pivot irrigation and water wells, became non-issues as a list of prioritized options were created based on the facts of each unique situation. Another unique strategy utilized by engineering and procurement was to bulk order a majority, but not all, of the material at the beginning of the COVID-19 pandemic. This allowed most of the structures and material to be ordered prior to the design of the lines to allow for a longer lead times. Once lines were designed that material would be “trued up” with what had already been ordered to created supplemental orders for the difference.

Construction Lessons Learned

One of the major factors that led to the success of the program was having construction contractors with sufficient expertise and resources. As the last major step on the conveyor belt of project success, the pressure is on the construction team to perform. Below, are four strategies used regarding construction contractors within the program:

- Engage construction contractors early in the project to ensure that trusted contractors can be used. This allows for them to reserve or allocate resources to the projects. This also enables input from contractors during the design phase, address ROW access information and pulling pocket locations.

- Build schedules to enable phased work. This meant again splitting a project into “mini-projects” to get multiple contractors on a single transmission line. This allowed the transmission lines to be completed in a staggered fashion rather than all at once which helped balance the workload of commissioning resources.

- Scope flexibility of the contractors was key. Halfway through the construction phase, we shuffled the contractors’ work assignments for the second half of the program. We had identified which crews moved more quickly and were better at various construction specialties, such as foundation or wire work, and we were able to adjust their scopes to set the program up for increased success based on the needs of various line portions.

- Finally, having valuable construction inspectors and construction management teams to ensure quality and verify progress was important to guaranteeing the program stayed on schedule.

The Need for Innovation

At the beginning of the program, teams were challenged to not settle for the reality of “the iron triangle.” A concept which states that one can achieve two of the three: good, fast, and cheap, but not all three. The underlying premise of the iron triangle is that processes and organizations are static and not changing. Often innovation is only thought of in a technical/design sense, but even small process innovations can make an impact. In some ways innovation was needed to stay the course, such as the many hurdles of COVID-19. In other ways innovation improved upon typical expectations, such as timelines. In this program we saw teams innovate in several ways including in design, project management, vendor management, procurement, and construction management. This resulted in what we believe to be a product that satisfies all the three corners of the iron triangle.

At the end of the day, the LP&L ERCOT Integration Program was about meeting a goal to serve customers. Teamwork across several utilities and multiple contractors overcame challenges and delivered a successful program. This teamwork was abundant between the regulated entities of Oncor and LP&L, as well as the many other stakeholders who coordinated and innovated together, delivering the program ahead of schedule, under budget, and within scope.