Prepared By:

Carrie Eberhard, P.E. – Vice President

Jeff Romine – Senior Environmental Specialist

Abstract

Stormwater management is a component of energy infrastructure construction that can be easily swept under the rug. Other aspects of construction may be perceived as a higher priority for “successful” project execution – delivery on time and under budget. However, the proper design, implementation, inspection, and maintenance of a project’s Stormwater Pollution Prevention Plan (SWPPP) is critical not only to compliance standards, but to the overall health and safety of the environment. Neglecting prioritization of stormwater management in initial project planning can lead to significant environmental impacts during and after construction and significant penalties associated with regulatory non-compliance. In this presentation, we will present the value of proactive stormwater management through a discussion that highlights the basics of a SWPPP, regulatory requirements, the value of early-stage stormwater management planning, and best management practices that you can implement today.

Stormwater Pollution Prevention Plan (SWPPP) Introduction

The simplest way of describing the overview of a Stormwater Pollution Prevention Plan is defining it as a detailed plan that lays out the steps and techniques used to reduce pollutants in stormwater runoff leaving a site. According to the EPA, “due to high erosion rates, construction sites are by far the largest source of sediment that pollutes water resources of the United States”. With that said, a SWPPP is commonly the most overlooked aspect of a construction project, even though it’s a requirement that must be in place prior to commencement of Earth moving activities. While SWPPP requirements vary by size and type of construction activity, the objectives of a SWPPP are the same from plan to plan. The main objective being to protect US waterways and surrounding receiving waters, the SWPPP lays out how to do so by offering Best Managements Practices (BMP) in accordance with state and local ordinances. The main ways of reducing sediment pollution are to control the perimeter of a site, reduce impervious surfaces to promote soil infiltration, protect slopes and channels, minimize the area and duration of exposed soils, and stabilize the site as soon as possible using pollution prevention measures.

In order to accomplish the objectives of SWPPP, it must be determined what type of construction activity permit is required. There are two types of construction permits, small construction activity permit or large construction activity permit. Starting with a large construction activity permit, those will include sites greater than 5 acres or part of a larger common plan of development. Examples of a site considered part of a larger plan of development would be master plan communities, commercial sites that are part of a larger retail or business center, or infrastructure such as roads or parks. Determining the total acreage to be disturbed and if a site meets the greater than 5 acre threshold, one must use the engineer designed civil drawings and measure out the acreage within the limits of construction. Another important factor to include is the acreage considered “Construction Support Activity”, which includes but is not limited to batch plants, equipment staging areas, material storage areas, access roads, etc. If a site meets these requirements, a Notice of Intent (NOI) must be filed with the state agency that will provide them with the primary operator information, which is the entity with day-to-day operational control of the site, and site details that includes acreage, receiving waters, past land use, start/stop dates, local Municipal Separate Storm Sewer System (Ms4), if applicable, as well as who to contact regarding the SWPPP. This NOI must be kept with the SWPPP and must be signed by the liable party, in this case the primary operator, in the event of compliance issues. In accordance with each state permit, a large construction site notice (CSN) must be posted containing the NOI information and readily available for viewing by the general public and/or enforcement. For linear projects it’s required to have the CSN relocated, as necessary, along the length of a project.

The other type of construction activity is small construction sites that are classified as sites greater than 1 acre and less than 5 acres. The implementation and maintenance of a SWPPP does not differ between the two types of construction permits. Small construction sites differ in that they do not require a NOI,

however, they do require a small construction activity site notice (SmCSN) containing contact and site information to be signed by both the primary operator and secondary operator (if applicable). A secondary operator is defined as a person or entity, often the property owner, whose operational control is limited to either the employment of other operators, such as a general contractor, to perform construction activities, or second, has the ability to approve or disapprove changes to construction plans and specifications. In most cases the secondary operator will sign on and participate in a shared SWPPP that covers the areas of the construction site where they have control over the construction plans and specifications. If there is not a primary operator at the construction site, then the secondary operator is defined as the primary operator and must comply with the requirements for primary operators.

Regardless of which type of construction activity a site falls under, a SWPPP is required and must be approved by the local city or county governing body before construction can begin. Additionally, an inspection frequency must be assigned to a site based on location and local ordinances and performed on that inspection frequency until temporary or final stabilization has been achieved. Most common inspection frequencies are either weekly, bi-weekly, or monthly and can vary due to local requirements, state requirements, or site location being in dry arid climates. It will require a trained third party or internal inspector to perform said inspections. Another important similarity yet variable aspect of determining inspection frequency is the requirement for rain event inspections, which in most cases is required when a rain event is over 0.5 inches of rainfall. This triggers the need for additional inspections outside of the normal inspection frequency and will be conducted in the fashion of pointing out deficiencies caused by the rain event itself.

Operator knowledge is key to keeping sites in compliance and enforcement out of the picture. While operators are not expected to know every detail of a site SWPPP that can be over 200-page documents, operators should know the answers to the following questions.

- Are all areas that will be disturbed by this construction activity permitted?

- Are all areas to be disturbed shown within the limits of disturbance?

- Are all runoff areas within the limits of disturbance treated by Best Management Practices (BMP)?

- Who is the Primary Operator and who is the Secondary Operator?

If for whatever reason a permitted area changes, such as a change in design, specifications, scope of work, etc., the operator or SWPPP preparer must be notified as soon as possible in order to amend the SWPPP. A change in permitted area is called a Notice of Change (NOC) and regardless of the site being small or large construction, this is a requirement to keep the SWPPP in compliance with local and state permits. In most cases this includes a change in Issued for Construction (IFC) civil drawings and for SWPPP purposes could result in a change in the Erosion and Sediment Control Maps (ESCP) that show location and design specifications for a sites BMPs.

On the topic of final stabilization and closing out a project SWPPP, the primary operator, not the general contractor, is responsible for all items within limits of construction. There is one exception to the rule and that is a ‘transfer of operational control’, which can occur when work transfers to an alternate standard industrial classification (SIC) permit code or the primary operator has transferred control of the site to the secondary operator. Transfer of operational control typically happens due to lack of payment, site work has been permanently ceased, or the secondary operator has requested control of the site back and is therefore accepting all responsibility of current site conditions. However, the standard practice for achieving a Notice of Termination (NOT) and closing a project is through final stabilization, meaning the site has established uniform, perennial vegetation that provides 70% or more of the cover that is provided

by vegetation native to local undisturbed areas. Additionally, the below requirements must also be met for NOT:

- Construction debris and trash has been removed

- Temporary BMP’s (such as silt fence) have been removed

- Any residual sediment has been removed

- Post-Construction BMPs are in place and operational with written maintenance requirements given to the appropriate party

- All drainage conveyances and outlets are checked to ensure that they were installed correctly and operational

- Inlet areas are inspected to ensure complete stabilization and any debris that could clog inlets are removed

- BMPs that will decompose, such as fiber rolls and blankets, may be left in place

These requirements and site conditions are part of what would be the final SWPPP inspection and must be completed prior to submitting the NOT. For drought and arid climates, final stabilization is met to the extent necessary when controls prevent erosion on the seeded or planted areas and non-vegetive erosion controls have been applied that provide cover for at least 3 years without active maintenance.

In summary, a SWPPP is a living and breathing plan that is constantly changing with the site from start to finish and must have constant and consistent recordkeeping to stay in compliance. If done correctly, sites could go the entire duration of a job without any enforcement or major maintenance costs that could out a strain on an already constrained budget. Ultimately, that’s the goal for execution of a solid Stormwater Pollution Prevention Plan.

Best Management Practices (BMP)

The term Best Management Practices (BMP) is frequently used to describe SWPPP requirements. A BMP is any measure, practice, or device used to reduce or eliminate the pollutants released from a site. The point of a BMP is to make optimal use of the operator’s resources to be fully sustainable without blowing the entire SWPPP budget on constant maintenance. There are two classifications of best management practices and they are a temporary BMP or a permanent BMP. Each particular BMP requires a detailed specification that gets placed in the SWPPP for reference when operators or general contractors need to install or maintain the BMP in question. Before installing any BMPs the installer must analyze the design needed to retain sediment onsite and if the area in question needs a sediment control device or erosion control device.

An erosion control device is a BMP that dissipates energy from raindrops and wind and can include erosion control matting, slope stabilization, geotextile matting etc.

Sediment control devices are BMPs that dissipate energy from flowing stormwater or sheet flow. There is a wide range of sediment control devices, including silt fences, check dams, inlet protection, fiber rolls, sediment basins etc.

It’s important to note that BMPs are intended to be preventative measures and not reactionary measures and they must be maintained during the duration of the project.

SWPPP Inspections & Compliance

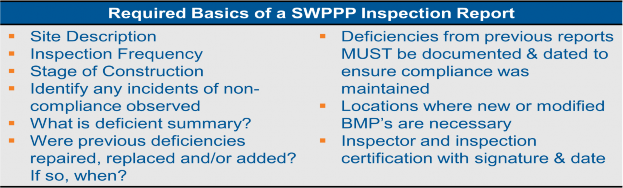

While inspection frequency is dependent on the criteria identified in the SWPPP, each inspection report must be filled out and conducted by a qualified and trained inspector who knows what to look for and how to appropriately write up corrective actions that explain how the site is out of compliance. For

liability assurance, best practice is for primary operators to subcontract third-party consultants and inspectors to perform this work, however, it’s not out uncommon for sites to have internal inspectors conduct these routine inspections. Below are the required basics of a SWPPP inspection report:

A common misconception when these reports are generated and filled out is that if corrective actions are written up it means the site is out of compliance. These reports are not enforcement but are simply qualified recommendations on how to fix a deficiency to keep a site in compliance with the SWPPP and keep enforcement away from a site. However, a site will become out of compliance and liable if those recommendations are ignored for periods deemed unacceptable by the local and state agencies. Primary operators must act on non-compliant issues onsite by either following the recommendations on the inspection report or finding alternative BMPs to correct the deficiencies. A safe practice for the SWPPP inspector is to keep diligent record keeping in the form of taking continual photos of the site in compliance and out of compliance and maintain an updated BMP tracking map that shows where and when BMPs are installed, repaired, replaced, or removed.

Communication is key in maintaining compliance throughout the duration of a project. The best way of maintaining that compliance is by correcting deficiencies ‘immediately’ upon discovery so that the corrective action never reaches any type of SWPPP report. A SWPPP will define the term ‘immediately’ as, “as soon as practicable, but no later than when Earth disturbing activities have temporarily or permanently ceased.” Operators need to ensure the inspection reports are quickly getting into the hands of the entity who will perform BMPs installs and maintenance. Ways of staying compliant and ensuring a clean report include managing stockpiles, minimizing slope disturbance, minimizing dust, preserving native topsoil, minimizing soil compaction, constantly sweeping roads of offsite tracking, having a designated area for concrete washout, and ensuring construction entrances/exits are operating per specifications. While all of this is easier said than done, it brings it back to why communication is key and proper training and proactive management practices on SWPPP requirements are necessary from the top (primary operator) to the bottom with each individual general contractor and personnel that comes on and off a jobsite.

The Future of SWPPP

With increased talks and debate around climate change, the common ground had amongst believers and non-believers is that we collectively have to do our part to reduce our contributions to the polluting of the planet we live on. Within all industries we are striving to improve on current methods to make the way we do everyday tasks and jobs more efficient – and that includes staying on top of SWPPP. SWPPP is not going away, and neither is a need to improve with each permit that gets issued by state agencies. In Texas, for example, the current Construction General Permit is set to expire on March 5, 2023 and once it does a new, revised permit will take its place. With each new permit the common rumors get thrown out that it’s going to have increased local and state enforcement, and with more enforcement comes higher risk of notice of violations (NOV) leveed on a jobsite, which result in fines and possible stop work orders. This is done not to take money out of a budget, but to encourage and promote SWPPP compliance. Other ways to promote SWPPP compliance are by increasing the inspection frequency or having rain event inspections required when rainfall reaches 0.25 inches versus 0.5 inches, which is currently the case in the state of Texas. Increased inspection frequency allows for operators to be more aware of the site conditions and it’s impacts on potential receiving waters when deficiencies on a report don’t get corrected as soon as practicable. Overall, changes in the new permit each state issues holds the operators and general contractors accountable for doing their part in staying compliant with the SWPPP and local ordinances.

The more exciting and fun part of the future of SWPPP is that states are now beginning to allow all SWPPP documents and recordkeeping to be fully electronic and no longer requiring printed hard copies to be kept onsite. In order to comply with electronic recordkeeping, SWPPP documents need to be made readily available upon request. One simple and efficient way of achieving that goal is through a QR code on the Construction Site Notice (CSN) that gets posted on all jobsites. Time will only tell what other proposed changes will be made to SWPPP, so staying knowledgeable about the changes and potentially sourcing third-party expertise, will give companies the edge on compliance.

Proactive Stormwater Management

In addition to staying knowledgeable and informed about potential changes, there are specific steps a company can take today to gain an edge on compliance. The philosophy that stormwater BMPs should be considered preventive measures, not reactionary controls, is a key tenant of proactive stormwater management.

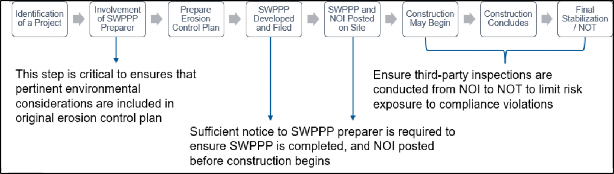

When a construction project is initially identified, the environmental consultant or designated preparer of the SWPPP should be informed. Involving the SWPPP preparer early and often throughout project development will ensure that any key environmental considerations are accounted for in project planning and in the erosion control plan. Following the completion of the erosion control plan, the SWPPP preparer needs to be notified with sufficient notice to prepare the SWPPP and file the appropriate permitting prior to the start of construction. Proactive involvement of the SWPPP preparer will help mitigate new questions or concerns from arising during the development of the SWPPP that may delay its completion.

It is crucial that the CNS (containing the NOI information) is posted on site prior to construction starting. This is a key milestone where neglecting the SWPPP in the project planning process can lead to both schedule and cost impacts should the start of construction be delayed. If construction were to begin without these items in place, Operators of the site would be subject to the enforcement actions discussed throughout this paper.

Upon the commencement of construction, the appropriate BMPs shall be installed by the erosion control contractor. These BMPs will have been designed as preventative measures, not reactionary controls, and it is therefore critical that they are installed and adequately maintained even if no erosion or runoff issues seem to be occurring.

Another way in which Owners can gain value from proactive stormwater management is by leveraging third-party inspectors to conduct the required SWPPP inspections from the start of construction through final stabilization. Making the conscious decision to utilize qualified, trained, SWPPP inspectors who report through an entity other than the Prime Contractor removes potential bias from inspection reporting and ensures that corrective actions are properly identified and completed. This ultimately limits risk exposure to compliance violations and ensures that BMPs remain a proactive measure rather than a reactionary control once a compliance violation or environmental impacts occur.

Enforcement

As previously mentioned, SWPPP inspection reports and identification of corrective actions is not the same as enforcement. When enforcement does occur, it can come from a variety of enforcement entities. A site is subject to enforcement under local ordinances (Ms4 or City), state authorities (TCEQ, etc.), federal authorities (EPA), or the general public who is able to file a complaint against the site’s construction practices.

Any enforcement that leads to a Notice of Violation (NOV) or further investigation can result in a Stop Work Order and fines up to $2,000 per day, per violation. While $2,000 per day may be a small cost impact compared to the overall project value, we must consider that additional cost impacts will likely be incurred due to the Stop Work Order and potential downtime or remobilization for construction contractors.

Primary Operators with day-to-day operational control of a site are subject to administrative, civil, and criminal penalties for violations including but not limited to the following:

- Negligently or knowingly violating the federal law or any condition or sections in the permit

- Knowingly making any false statement in any record or other documents submitted or required to be maintained under a permit. This includes reports of compliance or noncompliance.

- Knowingly violating law and placing another person in imminent danger or death or bodily injury

In March 2023, it is anticipated that there will be an increase in local and state enforcement, specifically in Texas. As the TCEQ prepares to public a new version of the General Permit on March 5, 2023, it is anticipated that fine amounts will increase to promote and emphasize the importance of SWPPP compliance. At least with the TCEQ, this includes modifying the rainfall trigger for rain event inspections, which has the potential to impact the frequency of required inspections.

Health, Safety, and ESG

In addition to wanting to avoid fine and penalties, a concern for health and safety should also be considered. Stormwater runoff from a construction site is unique compared to normal land use as there are many materials commonly used on construction sites that are considered pollutants, including but not limited to sediment, oil, pesticides, concrete washout, paint, and construction chemicals.

This stormwater runoff can lead to increased flooding, increased rate of erosion, and pollution of waterways. These harmful pollutants entering the watershed have the potential to change hydrology and water quality in both inland and coastal waters, cause habitat loss and modification, and decrease aquatic biodiversity. Further, human health can be impacted by the release of these pollutants when it is not controlled at the source.

In recent years, many corporations have placed and increased emphasis on sustainability and have implemented or adopted Environmental, Social, Governance (ESG) commitments. ESG is best characterized as a framework that helps stakeholders (investors, customers, contractors, etc.) understand how an organization is managing risks and opportunities related to environmental, social, and governance criteria. Stormwater management practices can influence ESG impacts in each area:

Environmental: As discussed herein, stormwater management has a direct impact on the environment by taking preventative measures to reduce environmental impacts including flooding, erosion, water quality, and biodiversity. Proactive SWPPP management has a direct impact on environmental commitments.

Social: In most ESG frameworks, one way that companies can demonstrate social responsibility is by holding their stakeholders to their own ESG commitments. This requires a proactive approach to stormwater management so that it is not delegated to a downstream entity (contractor) who will sweep it under the rug.

Governance: Utilizing third-party inspection services for all construction sites from initial inspection through NOT results in unbiased noncompliance reporting. This is an effective demonstration of risk management through governance practices and can limit liability from enforcement.

Closing

It is common for energy infrastructure projects to have goals that include delivering the project on time and under budget. While proactive stormwater management may not make the top of the list of project priorities, the goal of this technical paper was to demonstrate that this practice brings values in many facets of construction. There are many nuances to properly developing a SWPPP, filing the necessary permits, installing the BMPs, completing the inspections, and performing maintenance and repairs – each of which play an important role in proactive stormwater management. Having a basic understanding of these requirements is critical for any individual who plays a role in executing construction projects, however, having a dedicated SWPPP professional involved throughout the project lifecycle is a great way to ensure that it doesn’t continue to be SWPPP’d under the rug.